CNC | MILLING, TURNING AND GRINDING

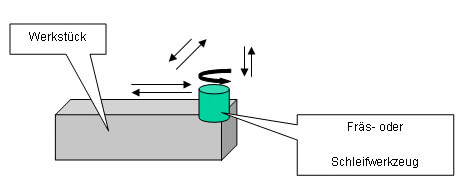

Milling of glass and ceramics

For milling, the firmly clamped workpiece remains immobile during the work process. Instead, the tool takes the programmed path around the workpiece, giving it the desired shape.

With 5-axis machining, Schröder Spezialglas is able to create almost any shape. The programs produced for these highly advanced machines are transferred via suitable interfaces.

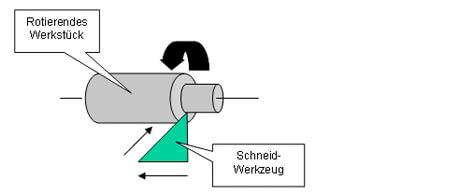

CNC turning of glass and ceramics

Unlike milling, for turning the tool is firmly clamped and remains static while the workpiece rotates against it.

For this process as well, the supplied programs can be produced at an external PC.

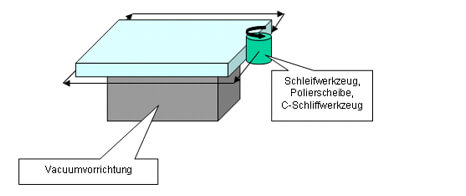

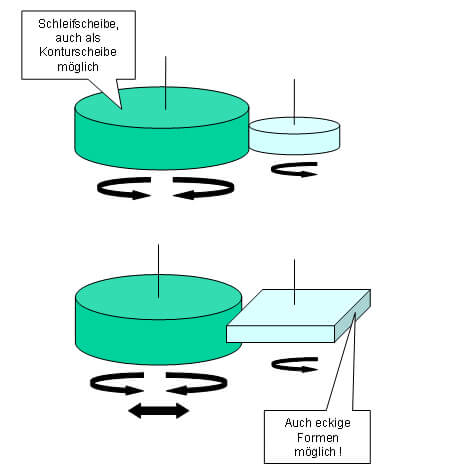

Edge grinding

Grinding is usually reserved for treatment of the edges. Schröder Spezialglas provides the following methods: pencil-grinding, facet grinding and edge polishing. This is done with a vacuum device, which is also used to firmly position large sheets.

Small glass sheets requiring contour grinding can also be clamped in a stack and processed with a diamond tool. Rectangular glass sheets can also be processed in this way.